covering materials

sale of greenhouse covering materials

Agrimec manufactures greenhouses and sells greenhouse covering materials: efficient, durable and strong, material specifically selected for your vegetable and flower growing.

the importance

of the materials

The covering materials represent the cost item where the maintenance interventions are concentrated. Therefore they must be durable, efficient and strong.

types of materials

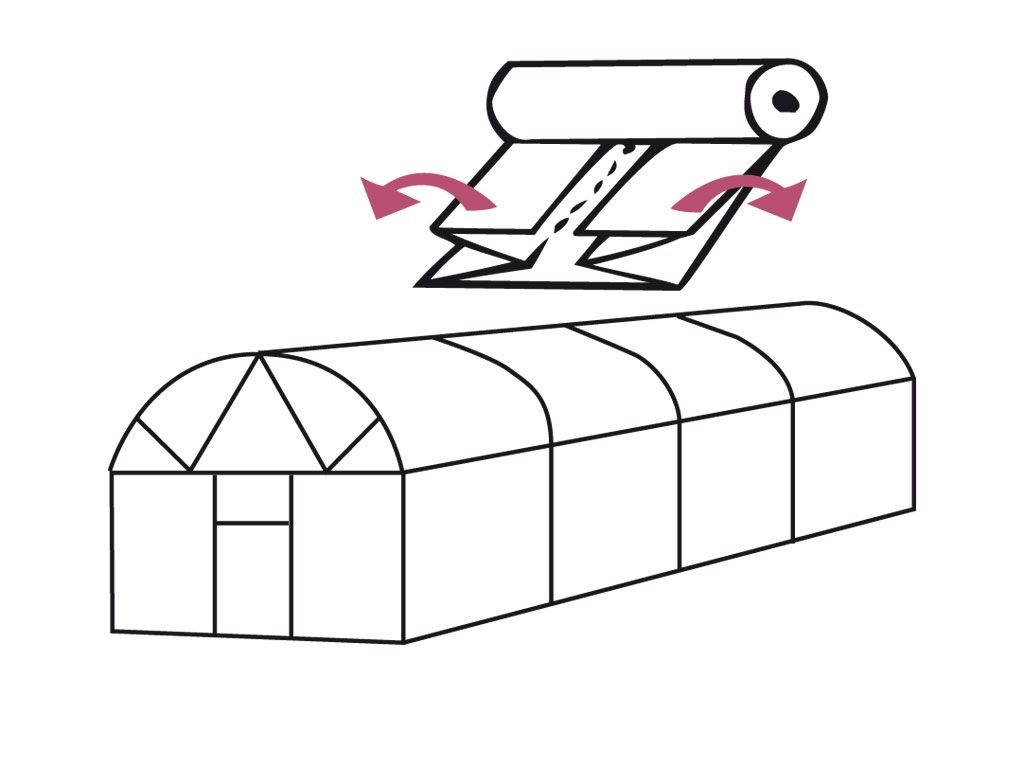

polyethylene film

PE

PE

| Brand | ||

| Structure format |

reels | |

| Installation | single | double inflated |

| Sizes available |

width da 2,5 ÷13,5 m |

|

| Thickness (mm) | 0,15 0,20 |

|

| Weight (kg/m2) | 0,20 | |

| Durata | 1÷4 anni | 3÷4 anni |

| Transparency | Duration 88% |

discreta 80% |

| Insulation | poor | good |

| Therm.expansion ter. mm/mK |

- | |

| reaction Fire |

- | - |

| Recommended to cover |

walls with roll-up window |

roof |

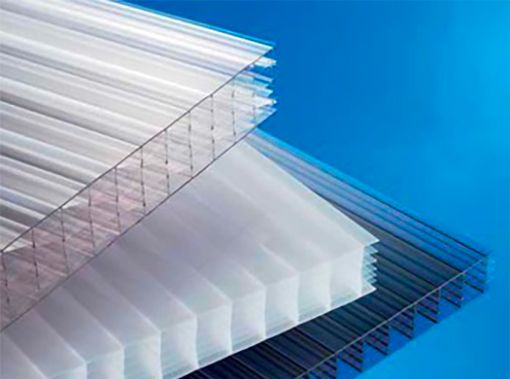

polycarbonate sheets

PC

PC

| Brand | |

| Structure format |

2 walls honeycomb |

| Installation | vertical cavities |

| Sizes available |

2,1 m x 6 m 1,5 m x 6 m 0,6 m x 6 m |

| Thickness (mm) | 6 |

| Weight (kg/m2) | 1,30 |

| Duration | 10 years |

| Transparency | fair 80% |

| Insulation | very good |

| Therm.expansion ter. mm/mK |

0,065 |

| Fire reaction |

class 1 |

| Recommended to cover |

wall fronts with up-down openings |

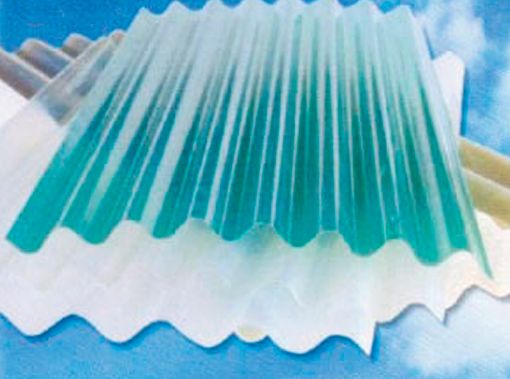

sheets

PVC

PVC

| Brand | Ondex Bio 2 |

| Structure format |

wave 76/18 |

| Installation | vertical wave direction |

| Sizes available |

width 1,112 m |

| Thickness (mm) | 0,9 |

| Weight (kg/m2) | 1,45 |

| Duration | 10 years |

| Transparency | very good 89% |

| Insulation | poor |

| Therm.expansion ter. mm/mK |

0,067 |

| Fire reaction |

class 1 |

| Recommended to cover |

wall fronts with up-down openings |

sheets

PC-PET

PC-PET

| Brand | Monoclear Ht |

| Structure format |

wave 78/18 |

| Installation | vertical wave direction |

| Sizes available |

width 1,08 m |

| Thickness (mm) |

0,8 |

| Weight (kg/m2) |

1,20 |

| Duration | 10 years |

| Transparency | very good 90% |

| Insulation | poor |

| Therm.expansion ter. mm/mK |

0,058 |

| Fire reaction |

class 1 |

| Recommended to cover |

fronts roof walls with up-down openings |

fibreglass

VR

VR

| Brand | Vetroplast | Elytop / Filon |

| Structure format |

rolls wave 76/18 |

sheets wave 76/18 |

| Installation | vertical wave direction |

vertical wave direction |

| Sizes available |

0,5x40m 1x40m 2x40m 2,5x40m 3x30m 3,5x30m 4x20m |

width 1,66 m 1,65 m |

| Thickness (mm) |

0,8 | not stated |

| Weight (kg/m2) |

1,00 | 1,45 |

| Duration | 6 years | 10 years |

| Transparency | fair 82% |

|

| Insulation | poor | |

| Therm.expansion ter. mm/mK |

0,027 | |

| Fire reaction |

self-extinguishing class 1 (on-demand) |

|

| Recommended to cover |

wall fronts with up-down openings |

fronts roof walls with up-down openings |

pvc sheeting

Poliester spalmato

Poliester spalmato

| Brand | |

| Structure format |

warp/weft 8×8 threads/cm |

| Installation | pull by elastic cord |

| Sizes available |

custom-made |

| Thickness (mm) |

not stated |

| Weight (kg/m2) |

0,63 |

| Duration | 8 years |

| Transparency | opaque |

| Insulation | poor |

| Therm.expansion ter. mm/mK |

- |

| Fire reaction |

self-extinguishing class 2 (on-demand) |

| Recommended to cover |

sliding fronts roof walls |

polyethylene film

Normative reference: EN 13206:2001

Film duration: determined following the procedure set forth by the normative reference EN13206, exposing plastic film in suitable devices equipped with specific lamps (which emit a radiation similar to that of the sun).

To determine film duration, the adopted criterion only considers material degradation obtained in a laboratory through accelerated artificial ageing (Weather-o-meter or Wom).

The duration of a covering material is proportional to the period of exposure to the artificial ageing beyond which mechanical properties are considered no longer efficient.

Film duration: determined following the procedure set forth by the normative reference EN13206, exposing plastic film in suitable devices equipped with specific lamps (which emit a radiation similar to that of the sun).

To determine film duration, the adopted criterion only considers material degradation obtained in a laboratory through accelerated artificial ageing (Weather-o-meter or Wom).

The duration of a covering material is proportional to the period of exposure to the artificial ageing beyond which mechanical properties are considered no longer efficient.

film classification based on accelerated artificial ageing

| Film class | Duration (hours) |

|---|---|

| N | ≥ 400 |

| A | ≥ 1700 |

| B | ≥ 3200 |

| C | ≥ 4600 |

| D | ≥ 6000 |

| E | ≥ 7300 |

relation between natural aging and accelerated artificial ageing for pe, eva and eba film

| Climatic area kLy/year |

Life expectancy of film (years) Time of exposure to Wom (hours) |

|||

|---|---|---|---|---|

| 1 year | 2 year | 3 year | 4 year | |

| 70-100 (Northern Europe) | 1700 | 3500 | 5300 | 7100 |

| 100-130 (Central Europe) | 2800 | 5600 | 8400 | |

| 130-160 (Southern Europe) | 3900 | 7800 | ||

North Italy 120 kLy/year

South Italy 140 kLy/year

South Italy 140 kLy/year

our proposal for polyethylene films

Classification:

Class E

Class E

Denomination:

AGRIMEC UV-EVA-AF

AGRIMEC UV-EVA-AF

composition/additives/duration

Composition:

coextruded – 3 layers

coextruded – 3 layers

Duration of the material:

stabilised UV

45 months for North Italy

33 months for Central Italy

21 months for South Italy

stabilised UV

45 months for North Italy

33 months for Central Italy

21 months for South Italy

Additives:

EVA (greenhouse effect)

AF (anti-fog)

EVA (greenhouse effect)

AF (anti-fog)

Colour:

neutral

neutral

dimensional features

Thickness (μm):

Class E

Class E

Thickness (m)

Available sizes

Folded 4 folds:

6 / 8 / 8,5 / 9 / 9,5 / 10

10,5 / 11 / 12 / 12,5 / 13,5

Folded 4 folds:

6 / 8 / 8,5 / 9 / 9,5 / 10

10,5 / 11 / 12 / 12,5 / 13,5

Folded 2 folds:

2,5

2,5

OPTICAL AND THERMAL FEATURES

Thermal effect:

80%

80%

Total transmittance

90%

90%

Diffused light:

22%

22%