-

Certified manufacturers

Certified manufacturers

-

Bespoke solutions

Bespoke solutions

-

From excavation to installation

From excavation to installation

-

Prompt maintenance

Prompt maintenance

Our engineering expertise is at your service, offering customised solutions for structural and electrical design, as well as site supervision. All activities are carried out by qualified technicians registered with the engineers' professional body, ensuring quality and compliance with current regulations.

Structural design

Upon specific request from the customer, Agrimec can provide the structural design documentation for its greenhouses, which includes:

- Structural calculation report prepared in accordance with the NTC2018 standards.

- Detailed executive drawings.

- Maintenance plan to ensure the longevity of the structure.

The structural calculations are carried out using the semi-probabilistic method based on limit states. The procedure adopted for the design can be summarised as follows:

- Identification of the structure’s usage class and its expected lifespan.

- Definition of the acting forces forces in both static and dynamic conditions, by identifying the load conditions.

- Preparation of load combinations (with corresponding combination coefficients) for the relevant limit states considered.

- Pre-dimensioning of the structural members.

Safety and performance

We ensure the safety and performance of the structures through a careful assessment of the limit states, taking into account the intended use, the nominal service life and the requirements set forth by the NTC2018 and EN 13031-1 standards. Specifically, the following checks are carried out:

- Safety at Ultimate Limit States (ULS): We ensure that the structure does not undergo excessive permanent deformations or collapse, either partially or completely. We also check that no damage occurs which could endanger people, lead to financial losses, cause environmental or social harm, or make the structure unusable.

- Safety in relation to seismic risk: We ensure that the structure retains its strength and rigidity under vertical loads during seismic events, with particular attention to the Ultimate Factor of Safety (FoS) for life protection.

These checks guarantee that the structure complies with the highest safety and durability standards, adapts to the expected stresses over time and minimises risks to people and assets.

Structural verification

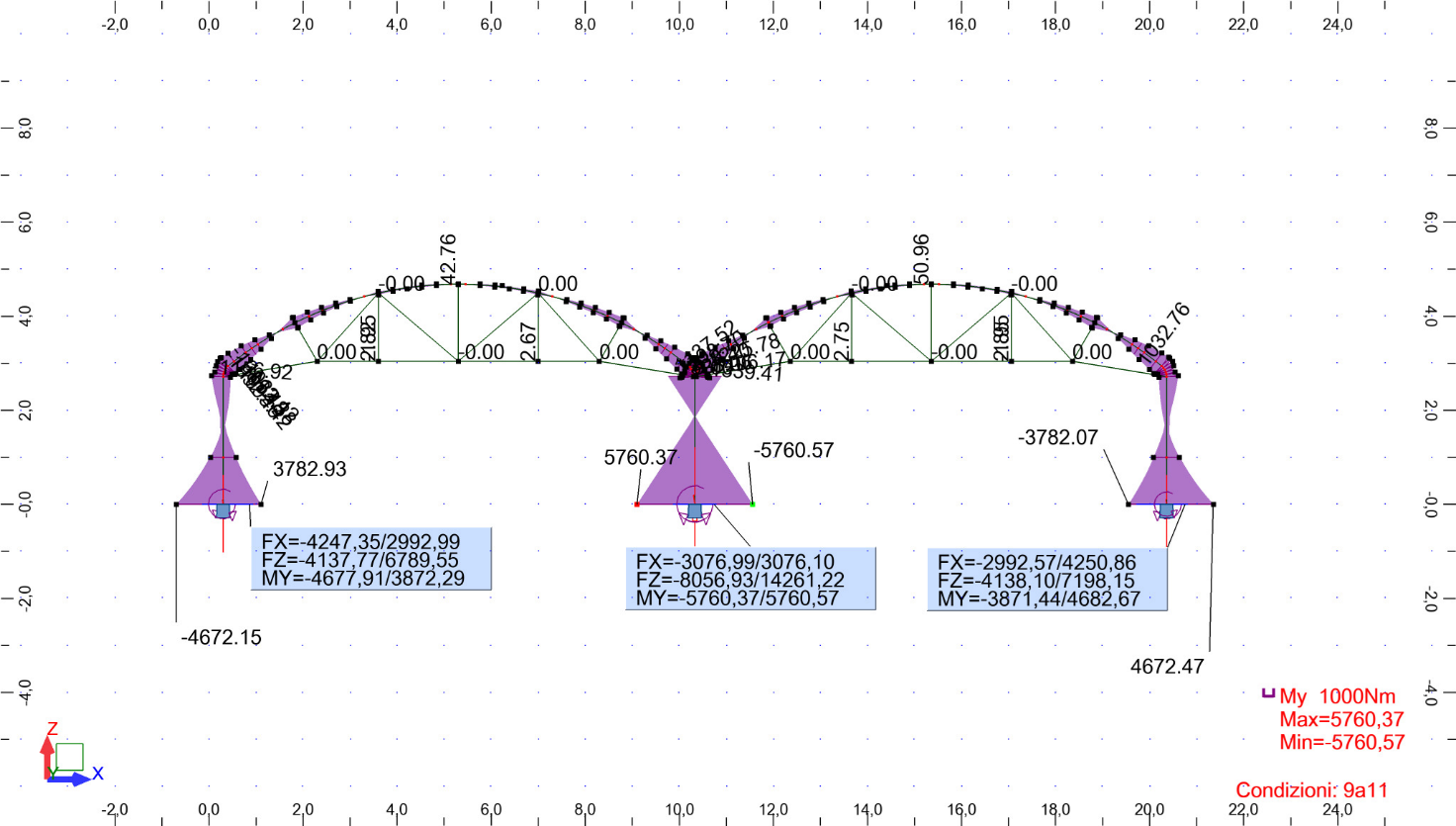

The structural verification is performed using a three-dimensional model that accurately replicates the mass distribution, stiffness and strength of the structure. For the calculation of stresses, the Finite Element Method (FEM) is employed.

The architectural design, including the three-dimensional modelling of metal structures, is conducted using Autodesk Revit software.

Stress calculations are carried out using Autodesk Robot Structural Analysis, an automatic calculation code for structural analysis of proven and established validity.

The structural analysis is performed using the following types of analysis, depending on the type of force considered during calculations:

The architectural design, including the three-dimensional modelling of metal structures, is conducted using Autodesk Revit software.

Stress calculations are carried out using Autodesk Robot Structural Analysis, an automatic calculation code for structural analysis of proven and established validity.

The structural analysis is performed using the following types of analysis, depending on the type of force considered during calculations:

- Linear Static Analysis when considering permanent, variable and exceptional forces.

- Modal Dynamic and Linear Seismic Analysis to assess the effects of seismic forces on the structure.

Site supervision

Upon the client’s request, Agrimec can oversee the seamless alignment between the project design and its execution, ensuring quality and regulatory compliance. The supervision of the construction process is entrusted to one of our qualified technicians, guaranteeing that the project is carried out correctly throughout the entire installation phase.

From a documentation perspective, the site supervisor provides a final report, which includes:

From a documentation perspective, the site supervisor provides a final report, which includes:

- Inspection certificates for structural metal materials issued by manufacturers (Type 3.1 test certificate in accordance with EN 10204).

- Declaration of Performance (DoP) No. X.20XX/1090-1/CPR.

- CE marking of the structural materials delivered to the construction site.

Electrical design

Electrical systems serving greenhouses, classified as productive real estate units, require a design prepared by a qualified technician, even in the case of extensions to existing installations. The Italian Ministerial Decree DM 37/08 regulates the installation of systems in buildings, including greenhouses, which Article 812 of the Civil Code defines as "structures attached to the ground, even for temporary purposes".

According to Article 5 of DM 37/08, an electrical design is mandatory if the system meets at least one of the following conditions:

According to Article 5 of DM 37/08, an electrical design is mandatory if the system meets at least one of the following conditions:

- Production units with a surface area exceeding 200 m².

- Presence of a medium-to-low voltage (MV/LV) transformer.

- Committed power exceeding 6 kW.

- Presence of high fire-risk areas.

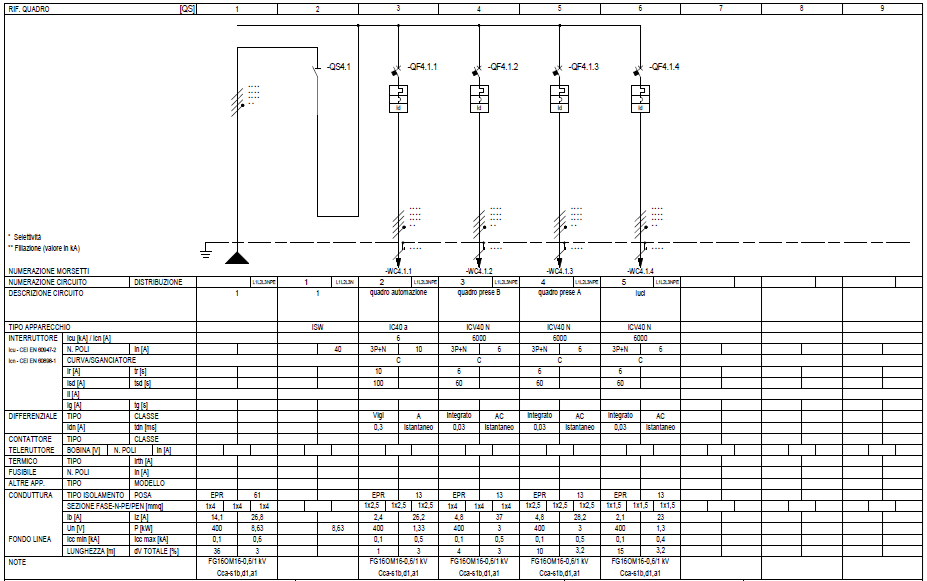

The electrical design, carried out by one of our qualified technicians, includes the final project for the electrical system, covering the distribution board and all electrical devices within the greenhouse. The documentation provided includes a technical report and drawings signed by the certified designer.

In particular, the electrical design carefully considers the specific operational requirements, especially in high-risk conditions.

The design includes:

In particular, the electrical design carefully considers the specific operational requirements, especially in high-risk conditions.

The design includes:

- A new magnetothermal residual-current circuit breaker in the existing panel for line branching.

- Overhead or underground conduit between the distribution board and the new main Greenhouse Panel (GP).

- Main Greenhouse Panel (GP), typically located inside the greenhouse.

- Automation Panel (AP), controlling functions such as automatic window opening/closing, forced ventilation, shading screens and fertigation systems.

- Optional Socket Panels (SP) to power additional devices.

- Overhead lines supplying AP and SP from GP.

- New circuits from AP for the equipment inside the greenhouse.

- A dedicated lighting system line from GP.

- A grounding system designed, to ensure the residual-current circuit breaker operates correctly in case of faults.

Our engineering expertise is at your service, providing tailored solutions for structural and electrical design, as well as site supervision.

If you would like to learn more or discuss how we can support your engineering projects, feel free to contact us.

If you would like to learn more or discuss how we can support your engineering projects, feel free to contact us.

Why should you choose agrimec, your strategic partner

Certified

manufacturers

manufacturers

- Creators and manufacturers of our product;

- EN 9001 process certification and EN 1090 product certification;

- High-quality materials: the only ones to use E260 steel.

Bespoke

solutions

solutions

- Agronomic consultancy during the project design phase;

- Technical and structural design, as well as system planning, to support the customer during the preliminary phase;

- Technical support during the system startup phase.

From excavation

to installation

to installation

- Installation by our in-house, trained and qualified staff, or with the assistance of trusted external companies who have been our partners for years;

- A single point of contact for the customer;

- From contract signing to system startup in under 60 days.

Prompt

maintenance

maintenance

- Three-year routine maintenance contract with periodic visits for preventative purposes

- Emergency maintenance service guaranteed if covered by a maintenance contract;

- Scheduled maintenance for the replacement of covering materials at the end of their lifespan.